Welded Sleeve System

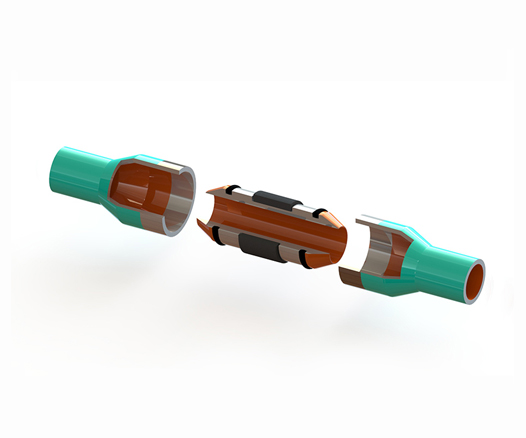

The ForceLok Welded Sleeve Pipe Joining System consists of an internal sleeve, advanced, engineered epoxy and a welded joint connection. The sleeve is sealed internally with an advanced, flexible engineered epoxy, designed to resist the high temperatures generated during the welding process. The internal sleeve incorporates an external, heat resistant shield designed to protect the sleeve and internal coating compounds during the welding process. The combination of the internal, epoxy bonded sleeve and externally welded connection, provides the highest level of strength and integrity available in a welded connection, delivering a smooth laminar flow in a holiday-free connection.

The ForceLok Welded Sleeve Pipe Joining System consists of:

- ForceLok Tooling

- Internal sleeve,

- Advanced, Engineered Flexible Epoxy

- A Welded Joint Connection.

The ForceLok End Preparation Equipment with ForceLok Tooling, fabricates the up-set, bell ends on the line pipe. The fabrication of the bell ends are monitored and recorded by the patent-pending ForceLok Computerized Monitoring System. The sleeve is sealed internally with an advanced, flexible engineered epoxy, designed to resist the high temperatures generated during the welding process. The internal sleeve incorporates an external, heat resistant shield designed to protect the sleeve and internal coating compounds during the welding process. The combination of the internal, epoxy bonded sleeve and externally welded connection, provides the highest level of strength and integrity available in a welded connection, delivering a smooth laminar flow in a holiday-free connection.

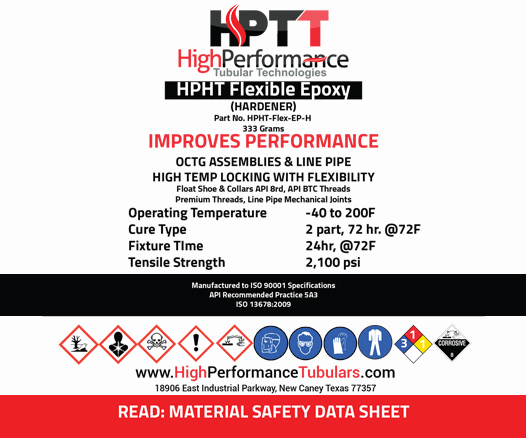

ForceLok Engineered Flexible Epoxy

The ForceLok Engineered Flexible Epoxy is a medium viscosity epoxy for applying to line pipe as a barrier to corrosion in joints and to aid in sealing. It is a 1:1 meter-mix formulation for use with all durable materials where water, moisture, commercial chemicals such as acids or harsh cleaning materials are present and need to be protected against. The product exhibits minimal shrinkage and forms a tough, flexible bond, which distributes stress over the entire bonding line to prevent cracking or separation. The ForceLok Engineered Flexible Epoxy is made to provide a slower cure to allow flexibility to develop, and has a low odor when mixed out of the special dispensing nozzles. This product has a work life of 50-60 minutes in the mixer tube, is tack free to the touch in 180 minutes at 72F, is fully cured in 24 hours and heat resistant to 250 degrees F during the welding process and has a cured operating performance rating of 200 degrees F. It has special adhesion agents for metal bonding especially damp or moist surfaces and will cure in temperatures down to 40F.